Precious Metal Clay (PMC) or Art Clay is a medium that has endless possibilities in the world of jewelry making. Without the need for a full workshop and lots of equipment, this craft takes very little space, a rather short amount of time, and can be a fulfilling activity with only beginning level skills. The end product is high quality pure silver (or gold, copper, or bronze) jewelry.

Precious Metal Clay was developed in Japan in 1990 by Mitsubishi Materials Corporation. Dr. Masaki Morikawa, a metallurgist and head of the manufacturing facility, invented a modeling clay made from the precious metal scrap left over from the gold used to make microchips. The first experiments were made with 24k gold. Soon after, Art Clay was created by scientists at Aida Chemical Industries. Both clays are made of very fine, ground particles of precious metal mixed with an organic binder. The flakes of gold or silver are so tiny that 25 of them clumped together is about a grain of salt.

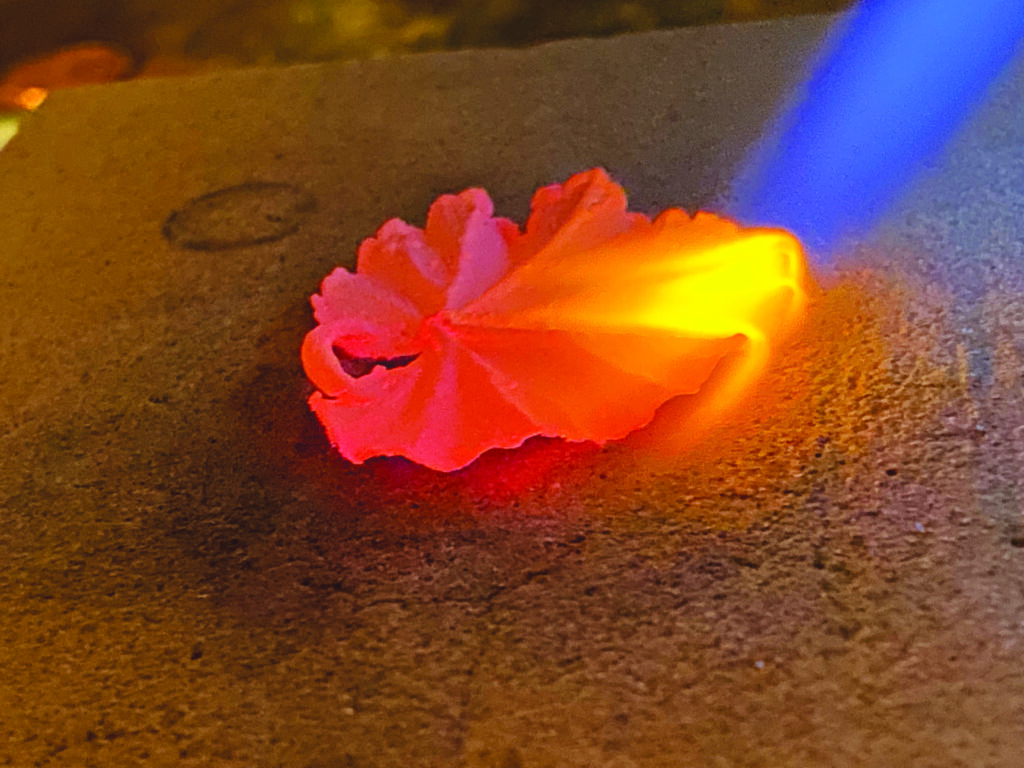

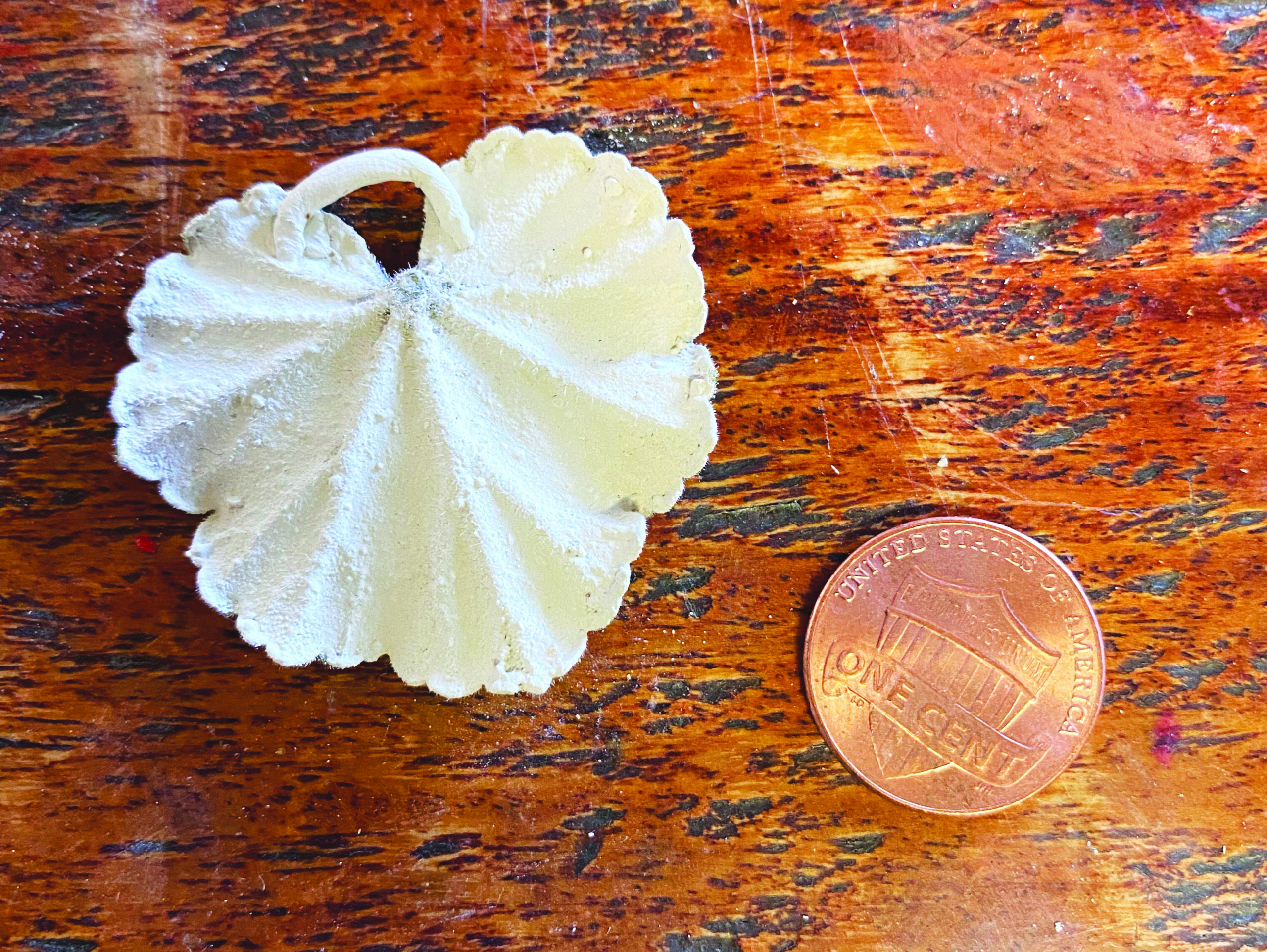

The clay can be carved, stamped, sculpted, extruded, painted, and molded into just about any shape. After the desired shape is created and allowed to dry, it is fired in a small kiln or, depending on the clay, even with a small butane torch. Since the development of the first clays, many different metal clays have been developed: bronze, copper, and sterling silver. Each metal has its specific strengths and attributes and has different firing temperatures and times.

The following photos are of projects using PMC-3 Silver clay. It is easily fired with a small butane torch. In the firing process, the binder is burned off and what is left is 99.9% silver. Pure silver is a softer finished product than sterling silver, and has a bright, light silver color. The 99.9% silver works beautifully for pendants, earrings, bracelet charms, rings, and nearly anything you can think of.